A COMPREHENSIVE GUIDE TO PURPOSEFUL SELECTION

CHOOSING THE RIGHT LIFTING HOOKS

In the world of material handling and lifting operations, selecting the appropriate lifting hooks is a critical decision that directly impacts the safety and efficiency of the task at hand. With a variety of lifting hooks available, each designed for specific purposes, understanding their characteristics and applications is essential. This article aims to guide professionals through the process of choosing the right kind of lifting hooks by exploring the unique purposes they serve.

-

purpose

sling hooks

Designed for use with lifting slings. Provides a secure connection between the sling and the load. Prevents accidental disengagement during lifting operations. Ideal for a wide range of applications where a reliable sling connection is crucial.

-

purpose

Eye Hooks

Features a closed eye for attachment to shackles, chains, or other lifting devices. Provides a stable and fixed anchor point for lifting operations. Versatile and suitable for various rigging configurations. Commonly used when a direct attachment point is required

-

PURPOSE

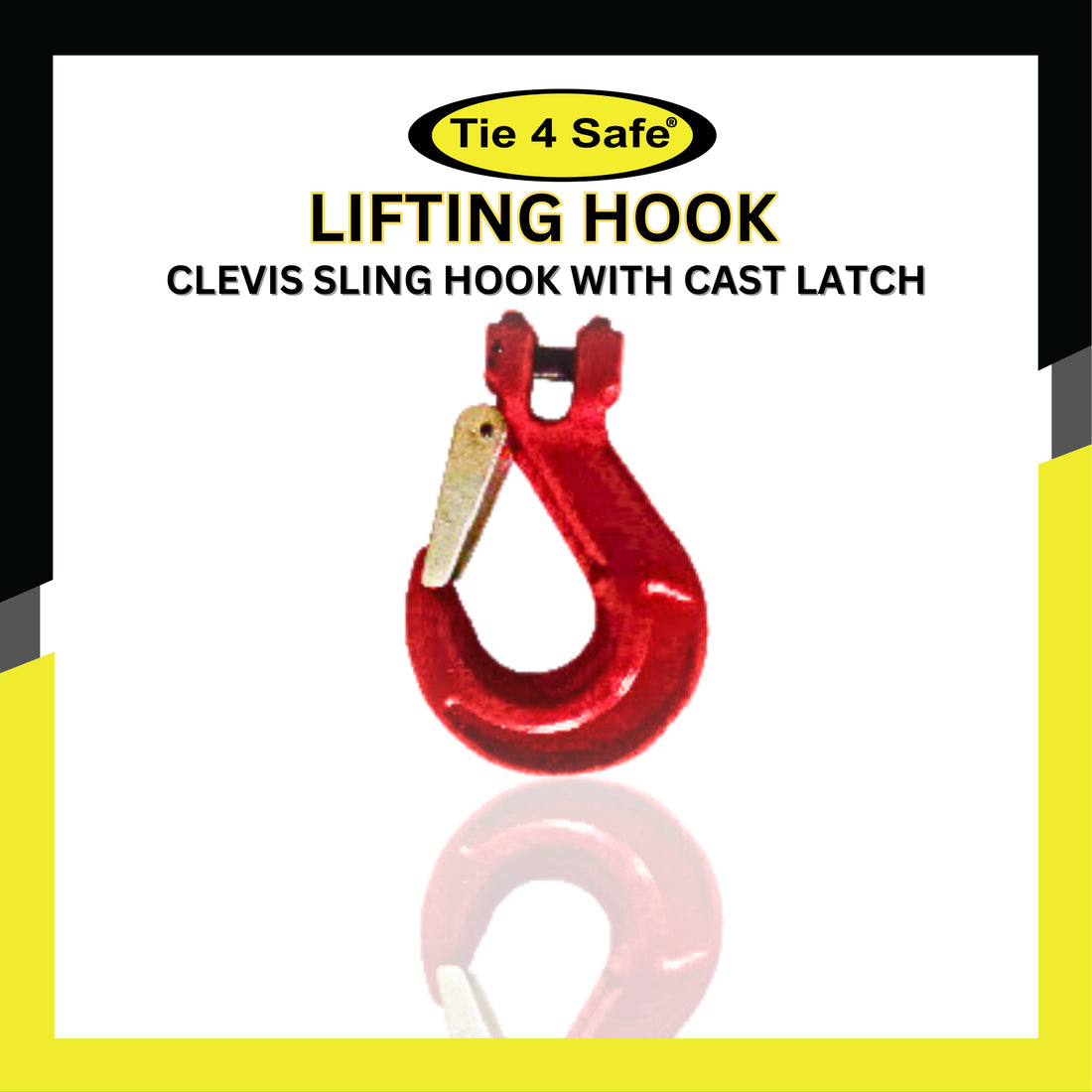

CLEVIS HOOKS

Equipped with a clevis pin for straightforward connection to chain assemblies. Simple design for ease of use in chain sling applications. Offers a robust and reliable connection. Ideal for tasks where a secure connection to a chain is necessary. ---> NEXT -

PURPOSE

GRAB HOOKS

Designed with a narrow throat and latch mechanism for a secure grip on the load. Suitable for applications where a tight hold on the load is crucial. Compatible with chain slings for effective material handling. Ensures the load remains securely in place during lifting.

CHOOSING THE RIGHT

LIFTING HOOK

Consider the Load:

Evaluate the weight, size, and shape of the load. Different lifting hooks have varying load capacities and are designed to handle specific types of loads.

Understand the Application:

Consider the nature of the lifting operation. For example, a foundry hook is specifically designed for high-temperature environments, while a swivel hook is ideal for tasks involving rotation.

Evaluate Environmental Conditions:

Take into account factors such as temperature, corrosion, and exposure to chemicals. Some hooks, like foundry hooks, are designed to withstand extreme environmental conditions.

Adhere to Safety Standards:

Ensure that the selected lifting hook complies with industry safety standards and regulations. Safety should be the top priority in all lifting operations.

Consult with Experts:

When in doubt, seek guidance from rigging professionals or consult with equipment manufacturers. Their expertise can help in making informed decisions based on the specific requirements of the lifting task.

Choosing the right kind of lifting hooks is a crucial step in ensuring the success and safety of lifting operations. By understanding the purposes of different lifting hooks and carefully considering the specific requirements of the task, professionals can make informed decisions that contribute to efficient and secure material handling. Rigging is an intricate field, and selecting the appropriate lifting hook is a key element in its successful execution.